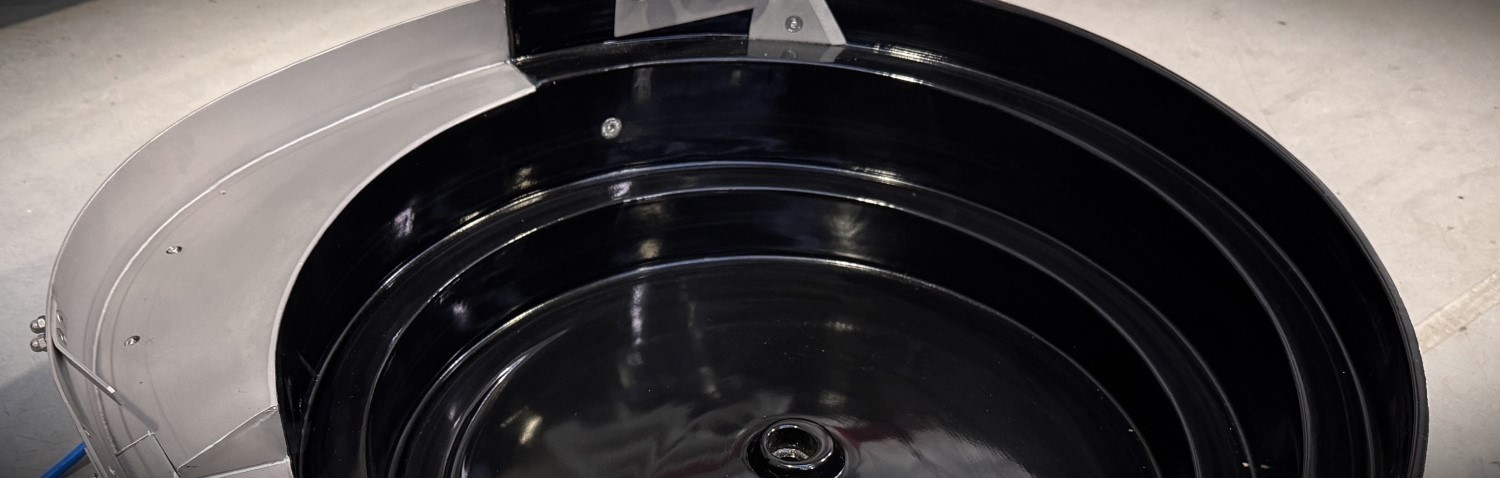

RNA Bowl Feeder Relining Service

Extend the life of your vibratory feeding bowls – fast, cost-effective, expert relining by RNA Automation

Why Relining Matters?

Keep Your Bowl Feeder Performing Like New

The polyurethane lining inside a bowl feeder plays a critical role in part handling, noise reduction, and overall performance. Over time, this lining naturally wears down—especially in high-throughput, abrasive, or continuous operations.

Relining is the most cost-effective way to extend the lifespan of your bowl feeder without replacing the entire system.

Relining prevents:

Result: A bowl feeder that performs consistently, reliably, and quietly.

Benefits of RNA Relining

Why Choose RNA’s Relining Service?

RNA uses industry-leading polyurethane materials and precision relining processes that restore the bowl to optimal operating condition.

Signs Your Bowl Feeder Needs Relining

Check for These Wear Indicators

Use this list to identify early warning signs:

- Cracking, flaking, or thinning polyurethane

- Smooth, shiny, or polished patches

- Exposed metal on tracks or base

- Increased vibration or noise

- Parts slipping, hesitating, or jamming

- Build-up of rubber/lining dust

- Bowl requiring higher vibration levels to operate

If you see any of these signs, relining is recommended.

Get a Relining Cost Estimate

Relining vs Replacing vs Refurbishing

Help customers understand the difference.

Which Option Is Right for You?

Condition | Recommended Service |

Lining worn, cracked, or thin | Relining |

Tracks worn, damaged, or misaligned | Refurbishing |

Bowl is older, geometry failing, repeated issues | Refurbishing or Replacement |

Only small components worn (springs/sensors) | Spare Parts |

Inconsistent feeding or vibration issues | Servicing |

Performance unstable even after servicing | Refurbishing |

Bowl older than 10–15 years or beyond repair | Replacement |

Compatible Bowl Types

We Re-line All Bowl Types Including:

- Standard vibratory bowls

- Step feeders (lining where applicable)

- Stainless steel bowl feeders

- Aluminium bowls

- Coated bowls

- Custom-built bowl geometries

- RNA systems and all major third-party brands

Why Choose RNA?

Europe’s Leading Bowl Feeder Experts

With over 50 years of experience in part feeding and vibratory technology, RNA provides unmatched reliability, support, and technical expertise.

You can trust RNA for:

- OEM-level knowledge

- High-quality polyurethane materials

- Industry-leading relining accuracy

- UK-based specialist engineering team

- Full lifecycle support (spares, servicing, refurbishing)

Contact

Send your message to a member of our services and spares team

Read our Privacy Policy to learn how we manage and protect your submitted information.