Downloads

A UNIQUE SOLUTION FOR FASTER AND MORE RELIABLE MACHINES IN THE YEARS

Years of experience and study in the field have allowed us to study and introduce numerous improvements in the details of our indexers and conveyors.

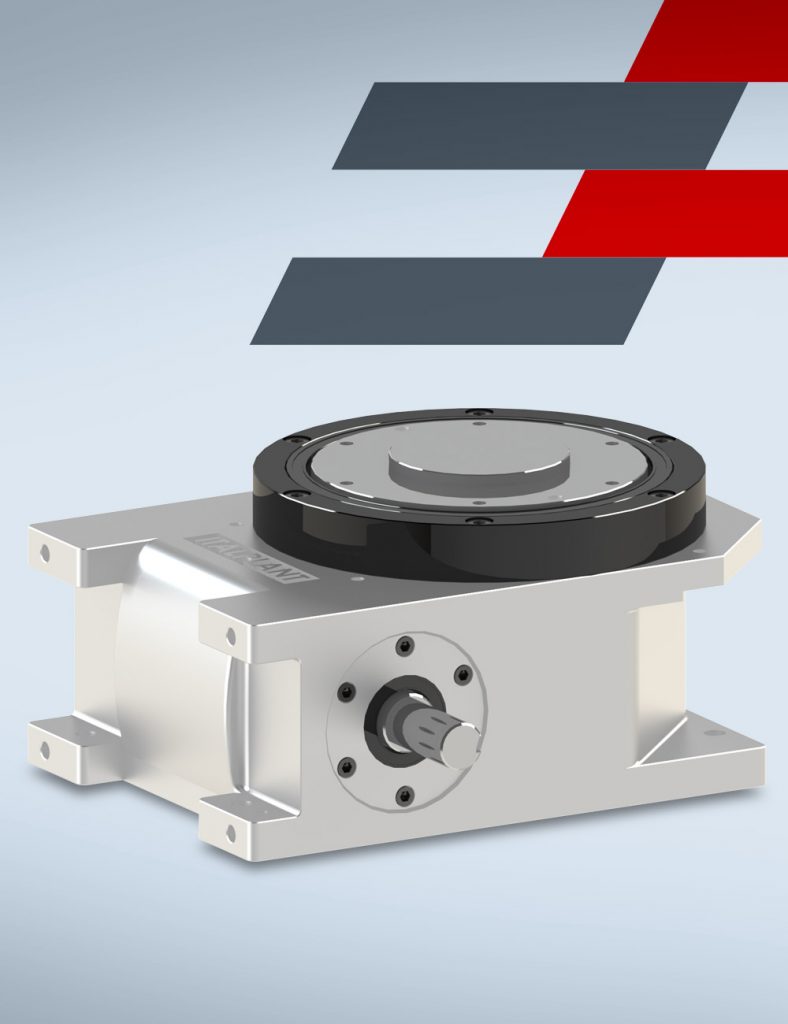

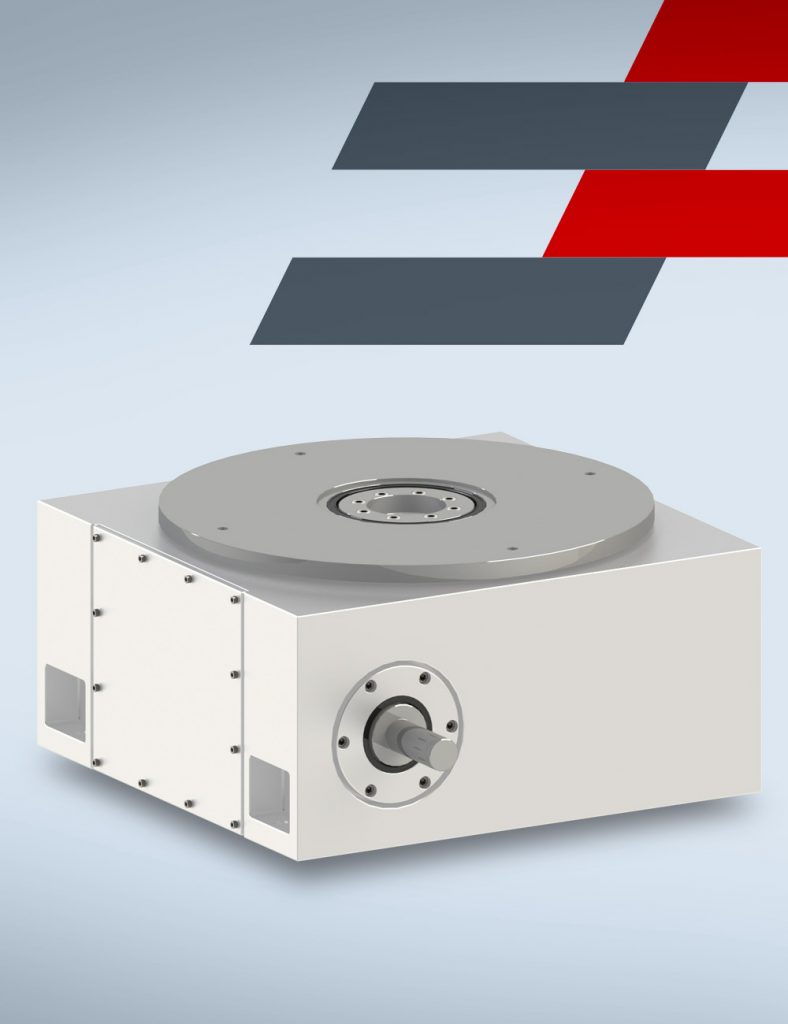

Among these, a peculiarity of our high-speed orbital cam machines is the possibility to include an Safety Output Torque Limiter (SOTL+ATL): it’s a unique system in the world and patented, that allows to introduce a torque limiter in a toroidal system thanks to which it is possible to install a safety clutch on the output axis.

In addition, our founder, patented (registration number 102013000010137) a new method for cutting high-speed cams, which makes our machines 30% faster than any other equivalent machine.

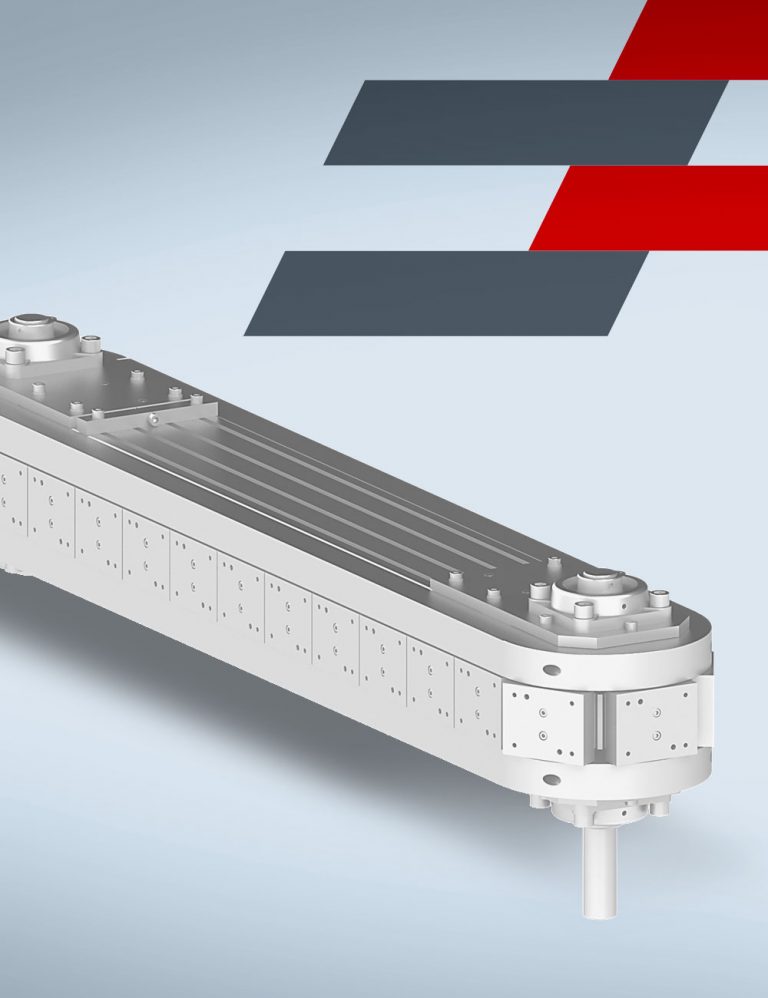

Finally, we patented some details of our PBC (Precision Belt Conveyor) and of our PLC-S (Precision Link Conveyor Square).

The rigour of each stage of our production process has also allowed us to achieve ISO 9001:2015 certification, which certifies our commitment to organize an internal quality management system.

Therefore, this certification guarantees the maximum efficiency of our production line, from taking charge of orders to the realization of components, up to the testing phase and sending to customers, always on time.

- BEST PERFORMANCE IN THE WORLD: To always guarantee the best production income, in any case

- ZERO BACKLASH: For accurate positioning of components

- SWEET MOVEMENTS: Governati da tecnologia sempre all’avanguardia

- ACCURATE POSITIONING: To limit any errors in the order of one thousandth of a millimeter

- HIGH LOAD CAPACITY: Able to work with the same level of precision with thousands of pieces

- NO VIBRATION: To further reduce errors and inaccuracies

- LITTLE MAINTENANCE: Once installed, our machines require no maintenance, and are guaranteed 5 years

- SAFETY DEVICES: Our patented SOTL+ATL system further enhances the safety of our indexers.

Italplant was founded in 1981, when our founder Giorgio C. Gay, a mechanical engineer, began collaborating with Manifold Indexing, a leading company in the United Kingdom in the construction of indexers.

The collaboration between Gay and John Reeve, theoretical mathematician at the head of Manifold, has given many results: among these, one of the most important is the design of a revolutionary series of MK1 cylindrical cam indexers, in addition to the revision of other large indexers, with globoidal cam and through hole.