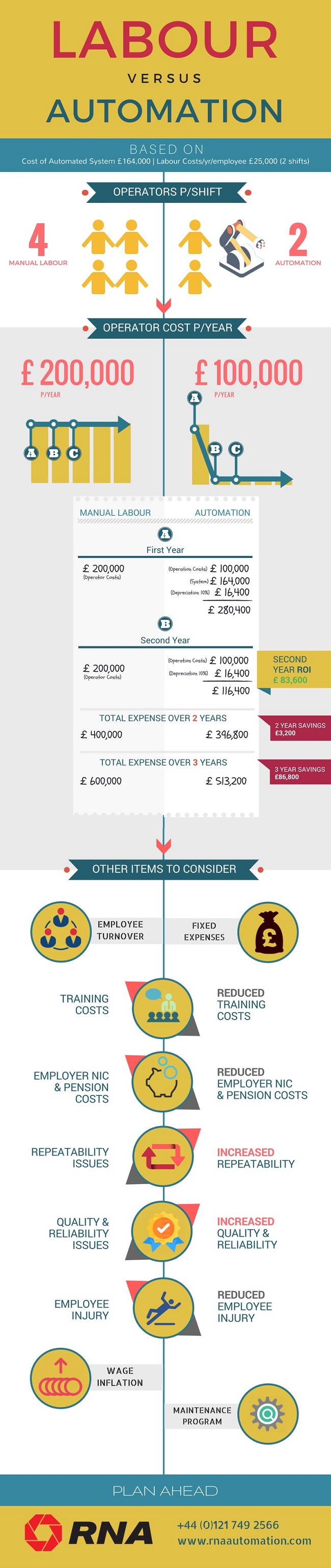

Cost of Manual Labour vs. Automation Infographic

Manual Labour vs. Automation One of the many benefits of automation is reducing manual labour costs. But due to the fear of the high initial cost, the investment in automation have been put on hold in many cases. We illustrate a case study by comparing an automated solution to a traditional solution to production, and the potential for payback or the Return on Investment (ROI).

In this case study, our customer was using 4 production operators x 2 shifts per day to meet their production goals.

RNA proposed an automated system, which require 2 production operators per shift. The automation included a rotary indexing assembly system & Poka-Yoke machine. The automation solved the challenges with their labour shortage, productivity and quality.

RNA helped the customer justify the cost of going automation. It was discovered that the annual cost per production operator was £25,000/year. They were using 4 operators/shift, 2 shifts/day. This equalled a significant amount at £200,000/year. This cost is just the labour salary and does not include other costs such as training, taxes and expenses that any business owners must pay.

The customer was proposed a total system cost to automate the process at £164,000. The new system still requires 2 operators/shift to load component parts. The cost of two labours is 2 operators at £50,000/year, 2 shifts/day = £100,000/year. The first-year’s depreciation on the system is £16,400 at a rate of 10% (10 years expected life cycle).

Depreciation calculation:

Annual Depreciation Expense = Cost of the system / Estimate Useful Life = £164,000 / 10 Years = £16,400

Therefore, their first-year expense for the system would be £164,000 plus £100,000 plus £16,400, totalling £280,000. This translates to a first year ROI of -£80,400 (£200,000 labour – £100,000 operators – £164,000 system – £16,400 depreciation ), a second year ROI of £83,600 (£200,000 labour – £100,000 operators – £16,400 depreciation ).

If the customer chose to not automate, their labour expenses would have totalled £400,000. With successful installation of automation their total expenses are £396,800. This is a savings of £3,200 over two years, and a savings of £86,800 over three years.

By working closely with the customer our engineers understand the customer’s needs and requirements, incorporating them into the automation system.

Download infographic PDF

So Automation or People? Plan ahead. RNA welcomes the opportunity to discuss and see if we can help you recognize similar savings in your operation. Contact us today!

You know your process and we know automation.

See other infographic: Top benefits of automation in manufacturing