Product:

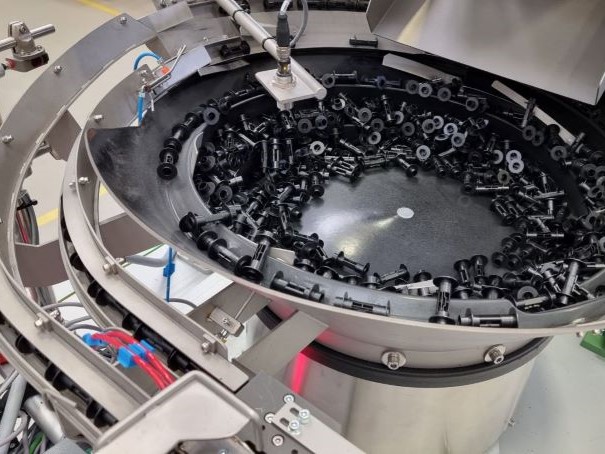

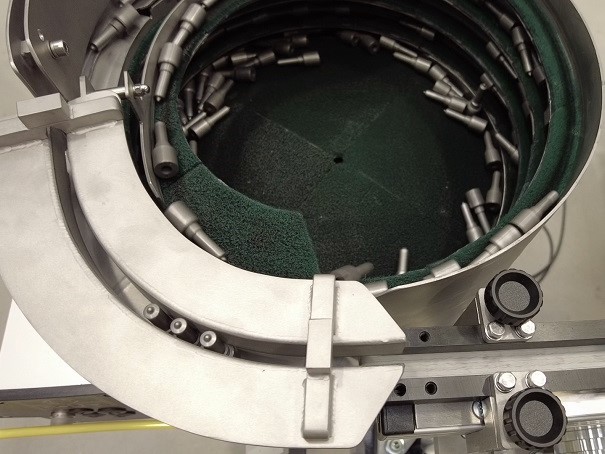

Terminals (25mm x 6mm x 0.8mm)

Performance:

2 components to be presented every 46 seconds

The system consists of:

- TAG-Z 200 Stepped Bowl top with PU200 polyurethane coating

- SRC-N 200-2 Vibratory Bowl Feeder drive unit CSA/UL Approved; ESK2000 Controller

- FP15E Mini-band Conveyor Out-feed; EBC3000 Controller for FP15E

- Robot Handling Unit Cobot UR3

Sequence of Operation:

The bowl feeder feeds and orientates terminals, fitted with a non-accumulation station to allow only one component part at a time to transfer to the conveyor out-feed.

The UR3 robotic handling unit equipped with a suitable gripper, collects one component part at a time from the conveyor out-feed and places it into a machined nest. The machine nest presents two component parts at a time for collection by the customer’s robotic handling unit into an injection moulding machine.