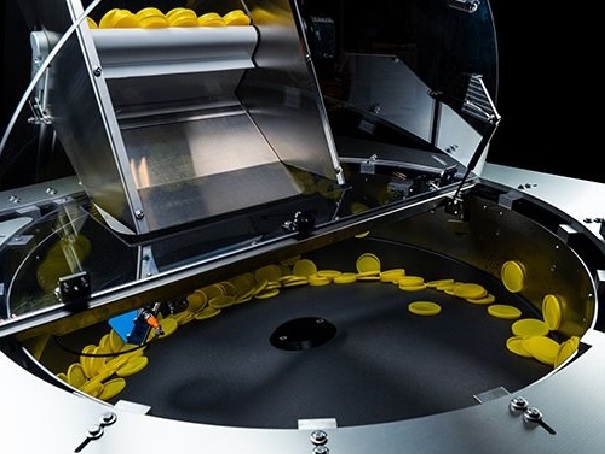

Product:

Range of Coin Blanks

(11 sizes total)

Performance:

A 1370 mm single row of components to be discharged every 6 seconds

Sequence of Operation:

Components are loaded manually by an operator into a bulk hopper and dosed into a centrifugal feeder which feeds correctly orientated components onto an outfeed conveyor. The conveyor transfers components from the centrifugal feeder onto a dead section of track. Back pressure pushes components the length of the dead section. Once the dead section is completely filled they are pushed at 90 degrees to the direction of feed off of the dead section onto the existing process conveyor.

Finishes:

Component contacts: Stainless grade 304, hard anodised aluminium. Non-contacts: Stainless grade 304, anodised/painted aluminium and painted mild steel.