Product:

Test Unit Body for medical use (Ø19mm x 40mm)

Performance:

50 components per minute, per lane. 4 lanes in total.

Sequence of Operation:

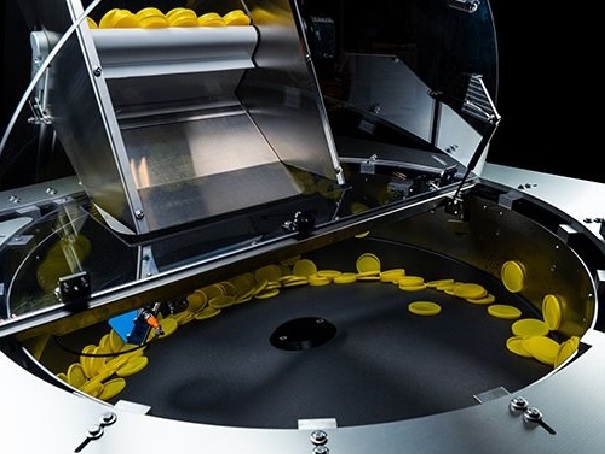

Components are loaded manually into two belt driven bulk feeders and doesed into two centrifugal feeders. Each centrifugal feeder correctly feeds and orientates components to a linear out-feed. The system comes with two single lane linear out-feeds with ‘v’ split to populate 4 lines at exit from linears.

Finishes:

Component contacts: Stainless grade 304 and FDA approved polyurethane, FDA HDPE, FDA polycarbonate.

Non-contacts: Stainless grade 304, anodised/painted aluminium and painted mild steel.

Paint Finish: RAL 9010