Product:

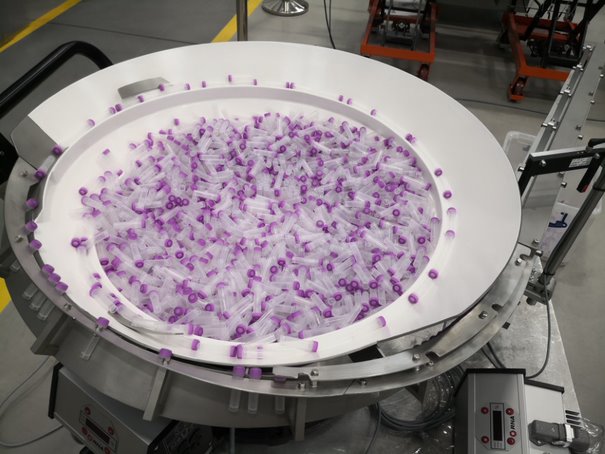

Caps (Medical Device)

Performance:

60 pcs/min

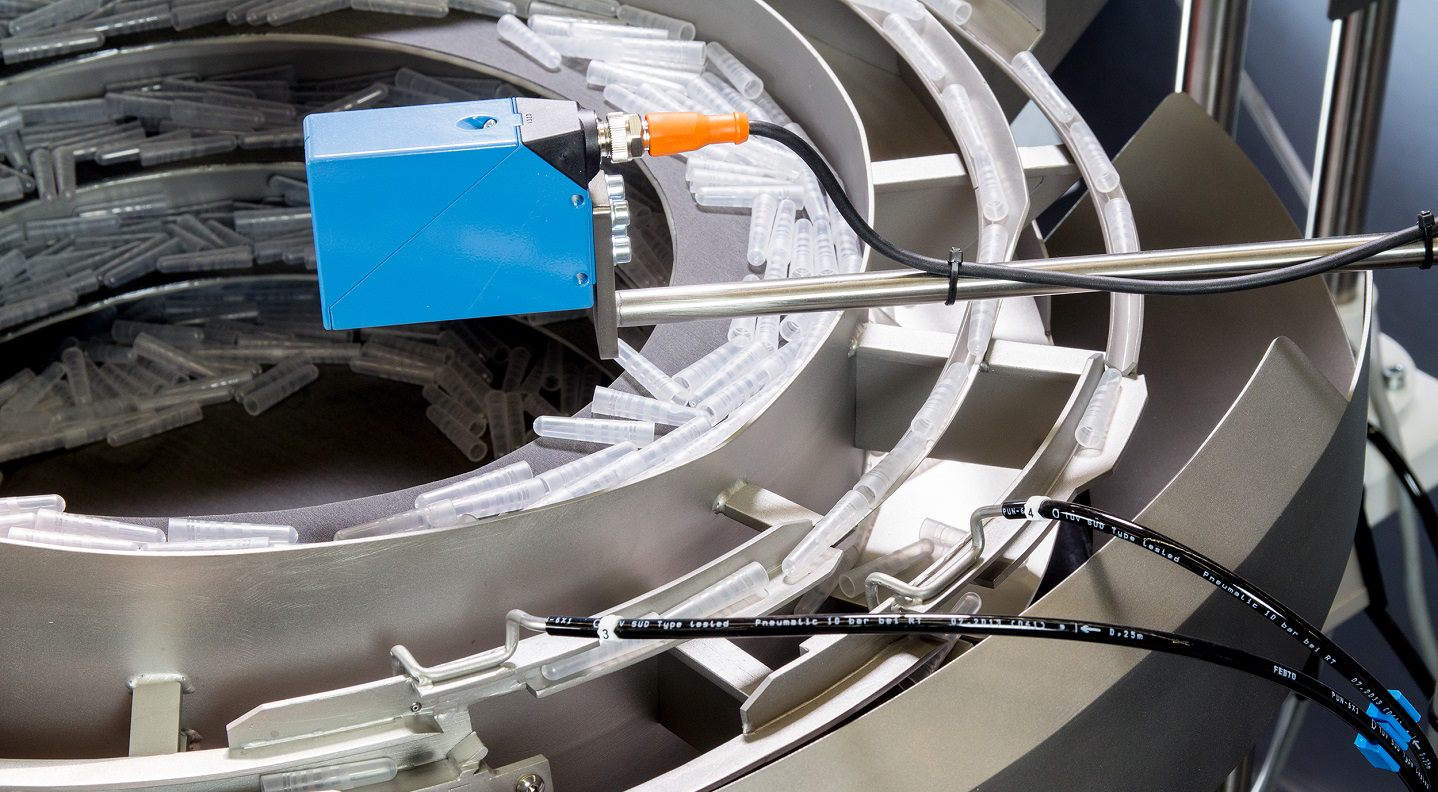

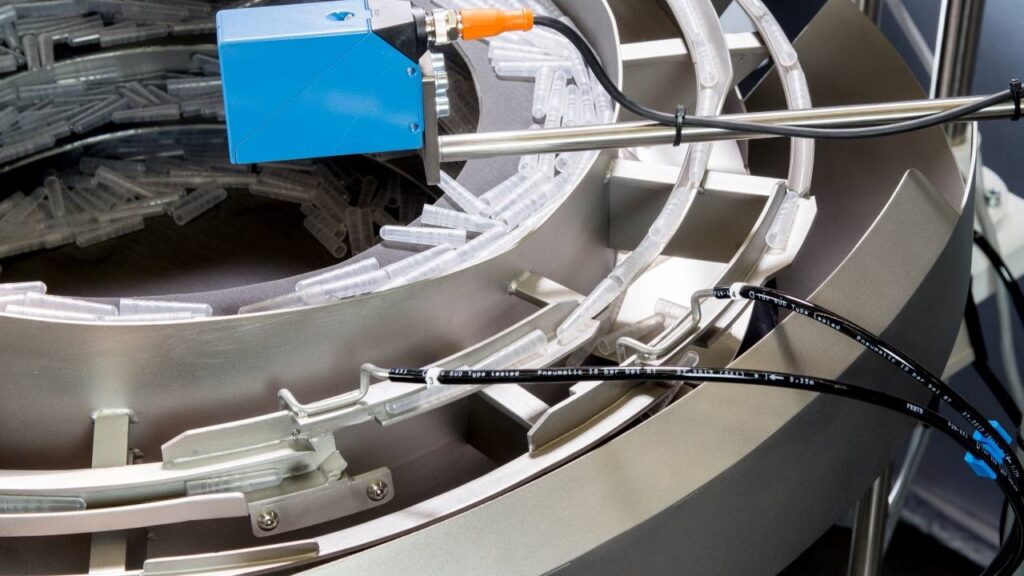

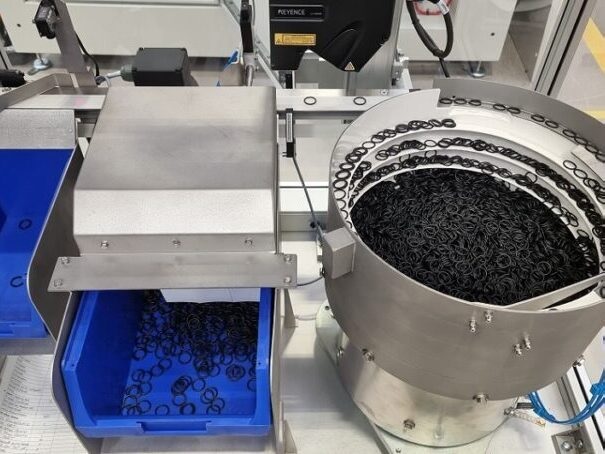

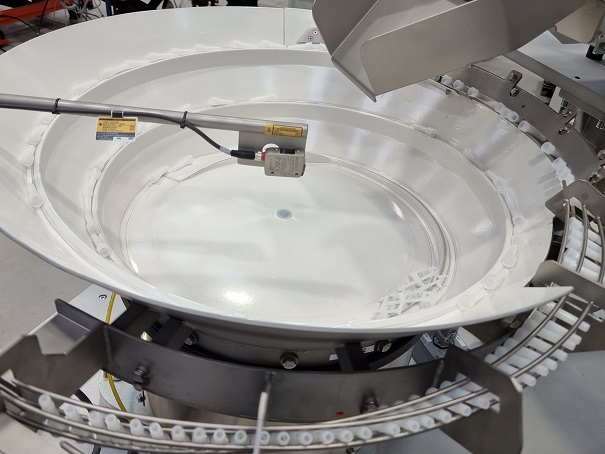

Bowl Type:

Cylindrical Bowl

The system consists of:

- ZSB 400 bowl top

- SRC-N 400 Bowl feeder drive unit

- BUW Hooper

- Controller

- Gravity track

- Electric slide side shuttle escapement

Sorting in the vibratory bowl feeder (rotary feeder) with a dual-track outlet. After sorting, there is a 90° turning of both tracks, in order to transfer the parts onto a ready carrier plate (8-fold).

The carrier plate is then turned by 180°, so that the required take-off position at the customer’s interface can be put into effect.