Solution

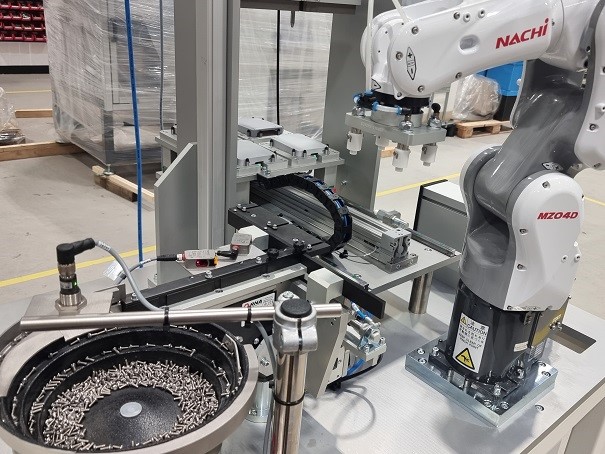

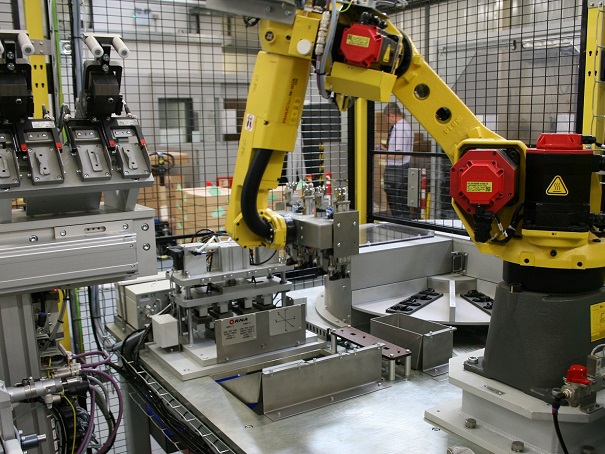

The project involved the supply of four machines, one of which was an automated robot clipping and welding system. This consisted of 2 high speed 6-axis robots for clip presentation and insertion, one welding robot with ultrasonic welding head, 2 bowl feeding systems and 2 printers.

The project involved the supply of four machines, one of which was an automated robot clipping and welding system. This consisted of 2 high speed 6-axis robots for clip presentation and insertion, one welding robot with ultrasonic welding head, 2 bowl feeding systems and 2 printers.

The robot clipping and welding system has independent right and left hand stations, each including a mirrored assembly fixture for a left hand or right hand automotive panel. The system is semi-automated in operation with an operator loading 2 types of automotive panels into fixture nests and then unloading the completed assembly. The 6-axis robot picks and accurately assembles spring clips onto the panels, whilst a welding robot ultrasonically welds and joins two panels.

The vision inspection features and poka-yoke (error proofing), ensures that all spring clips are correctly present / fitted. Once the full processing cycle is completed, the printers print barcode labels, which will be attached to the panels by operator before the unloading.

The remaining three machines are all semi-automated clipping systems with bowl and linear feeder(s), 6-axis robot(s) for clip presentation and insertion, plus label printing station(s). The poka-yoke design ensures all spring clips are fitted in position.

Videos are available on request.

Get in touch with us to discuss your requirements and we will be happy to visit you and offer our professional advice.