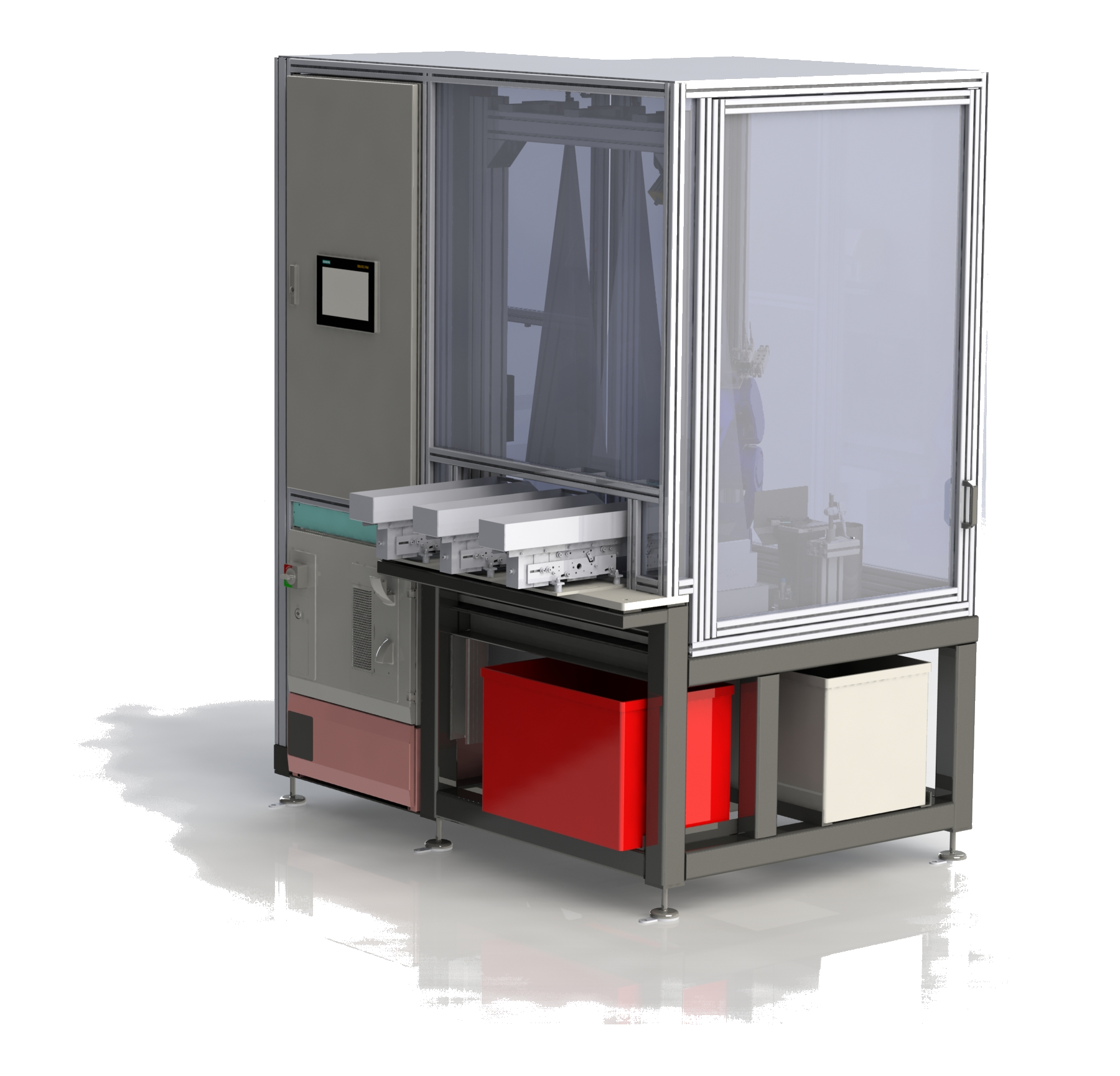

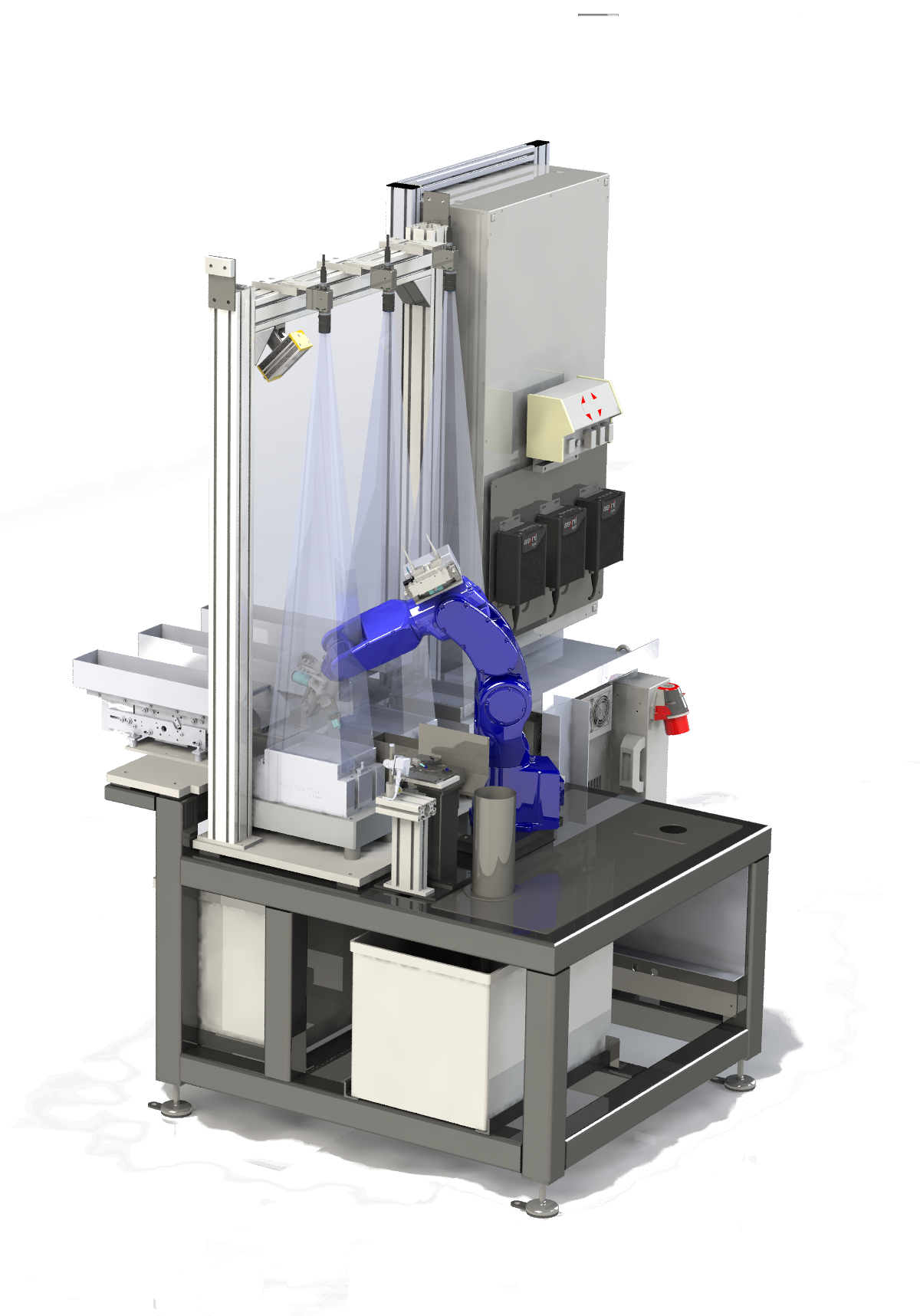

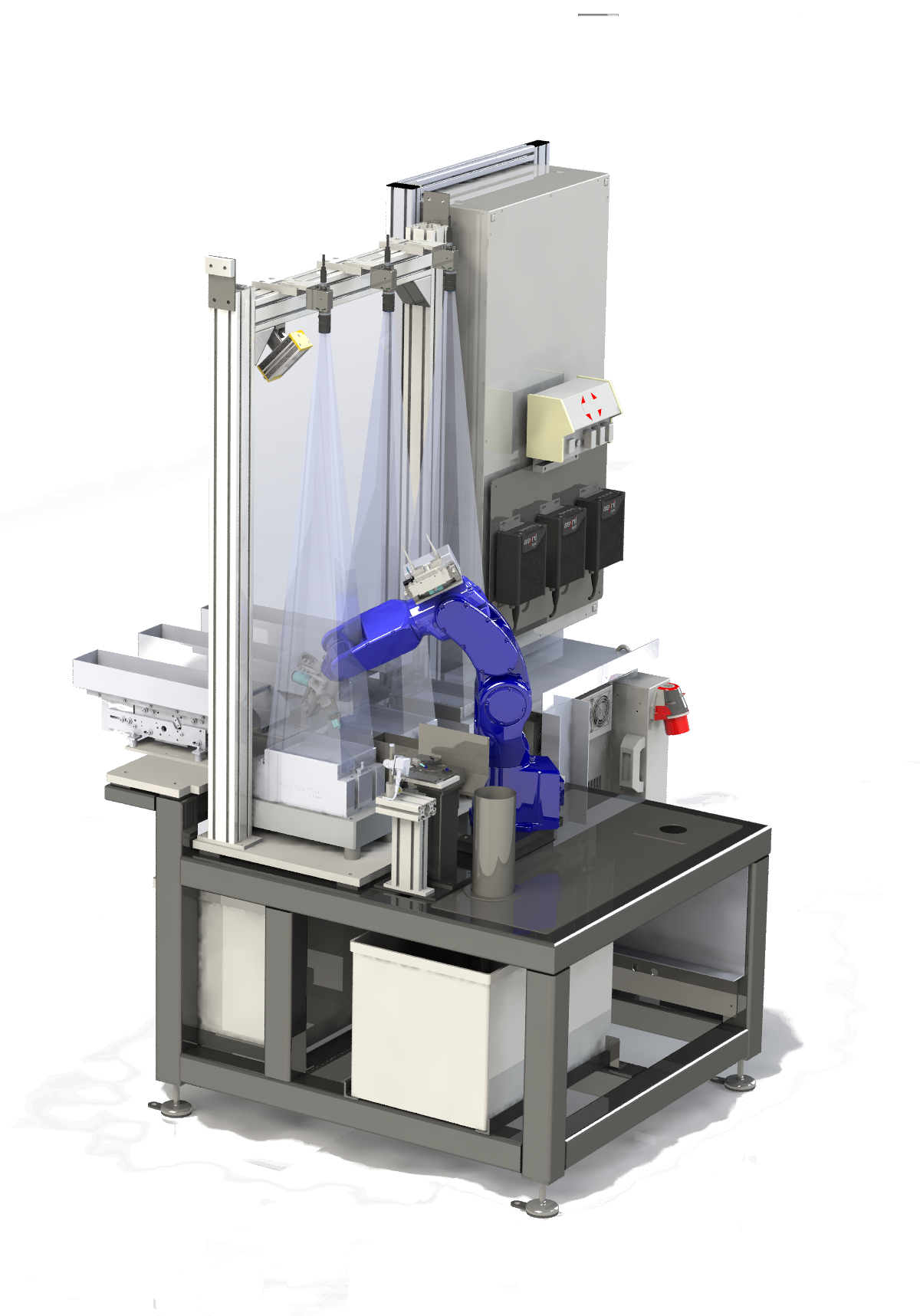

VariCube R™

A STANDARD FLEXIBLE ASSEMBLY SOLUTION

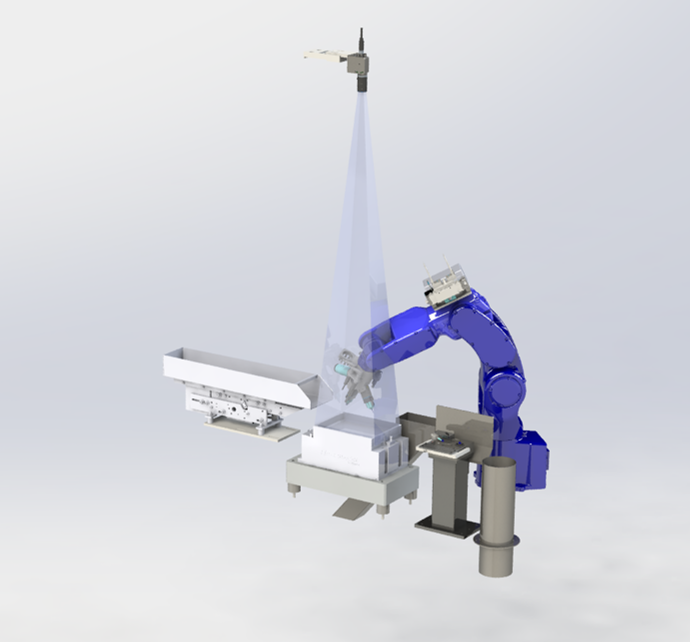

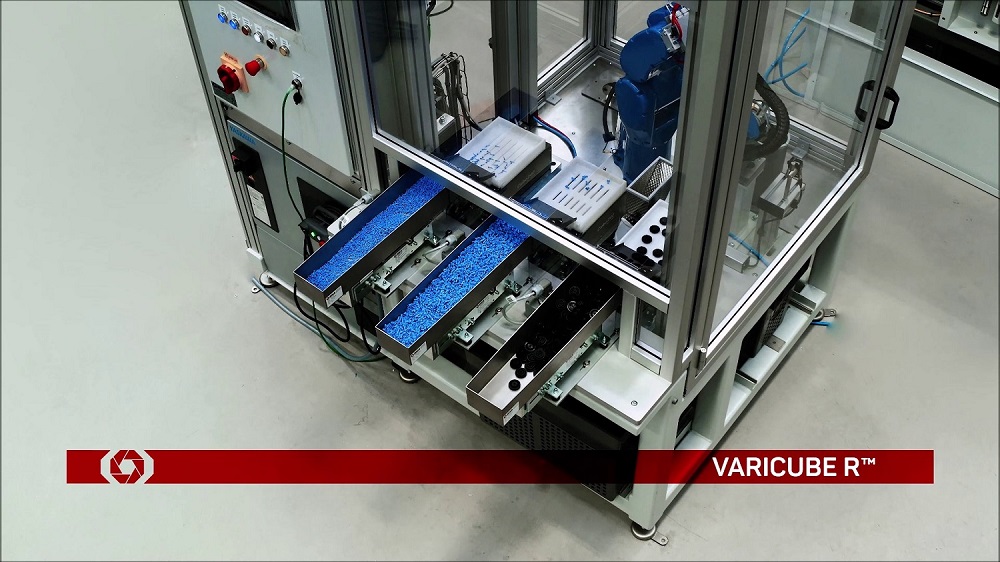

RNA’s VariCube R™ presents a flexible assembly solution that utilises intelligent vibration platforms, coupled with industrial machine vision recognition and a 6-axis robot to feed and assemble component parts of various shapes and sizes.

Downloads

Suitable for

Parts from 0.1mm to 150mmIncluded in VariCube R™ Flexible Assembly Machine

VariCube R™ | RNA FLEXIBLE ASSEMBLY MACHINE

FLEXIBLE, RELIABLE AND STANDARD SOLUTION FOR THE AUTOMATED ASSEMLBY IN 6 STEPS

STEP 1: Various parts to be assembled are loaded in bulk into hoppers. Parts drop by vibration from hoppers onto FlexCube backlit vibratory platforms on demand.

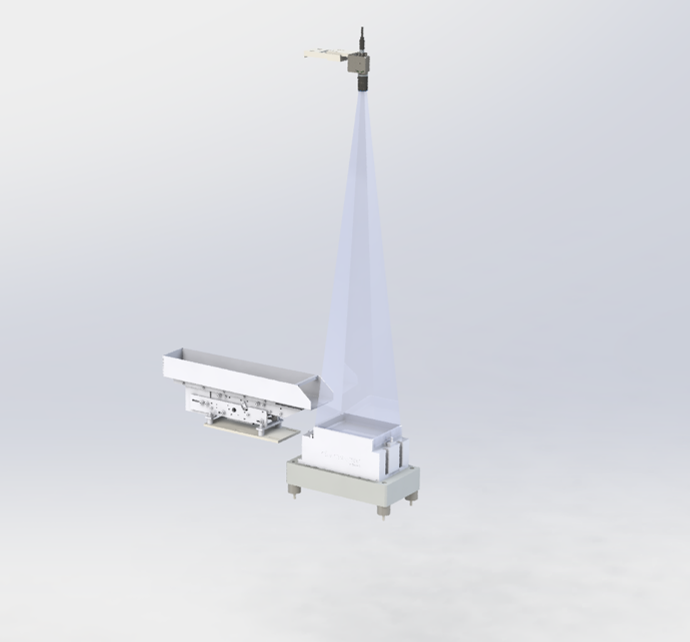

STEP 2: The FlexCube complete pre-programmed vibratory cycles to orientate and separate component parts, presenting them to an integrated EYE+ vision system for robot pick.

STEP 3: The EYE+ vision system inspects the component parts on the FlexCube platforms and identifies which are laying in a position suitable for being picked. The coordinates are sent to the robot.

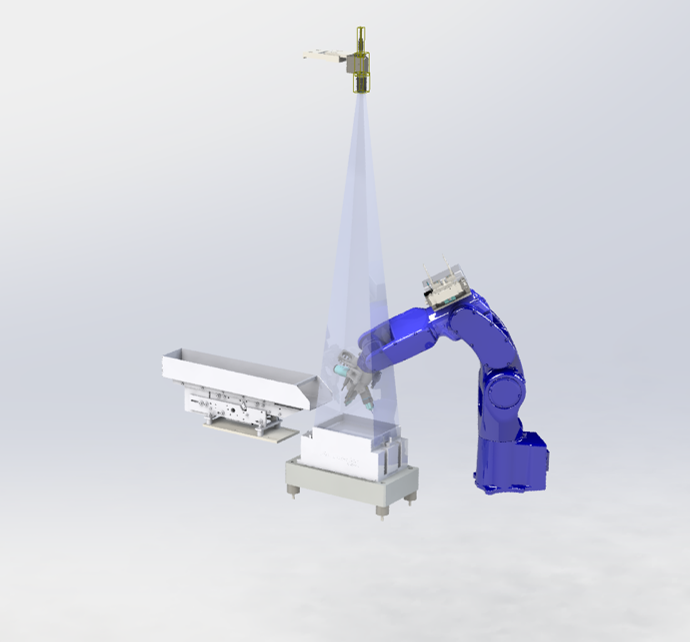

STEP 4: A 6-Axis Robot, with suitable end of arm tolling picks all identified component parts and places them in the proper orientation into the assembly nest.

STEP 5: The customisable nest is located by dowels for interchangeability and incorporate part present sensing. An overhead mounted vision system confirms positioning of the component parts before final assembly.

STEP 6: The robot unloads assembled component parts to a storage box via an unload chute.

Flexible feeding

- Alternative for vibratory bowl feeders

- Experience seamless, software-based part changeovers in minutes

- Easily process a wide range of part sizes and shapes

- Handle multiple variants of a component part or parts with complex geometry

Flexibility for part changeover

- Interchangeable FlexCube™ platform for pre-orientation of the parts

- Teachable vision system

- Auto calibration of the vibration parameters

Easy handling of variants

- Variants are stored by the controller

- Only 2 minutes to bring a new variant into production

Short delivery time

- Fully standard

- Pre-designed

High reusability

- More than 95% reusable (less investment)

- Specific tooling reduced to the minimum

Fast implementation

- Standard platform

- Standalone Package with Integrated Controls

Easy configuration and installation

- Quick setup and reprogram to perform a different application

- Fast and easy configuration adjusting to changes and demands

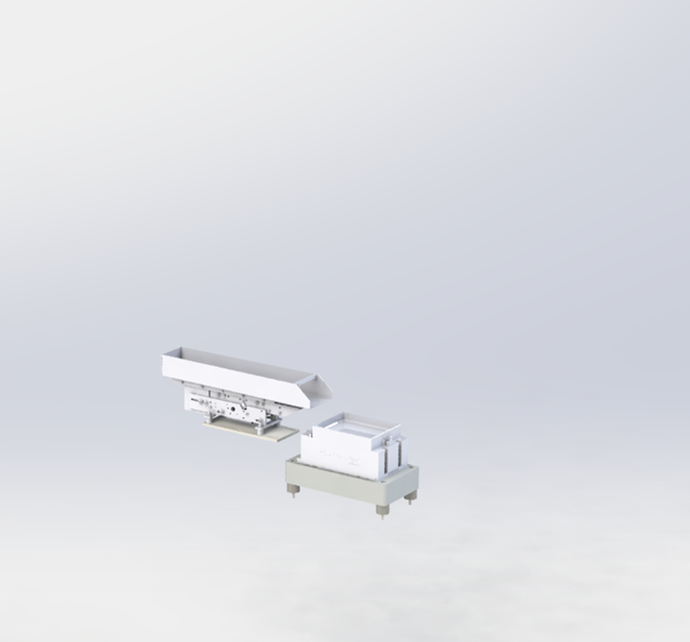

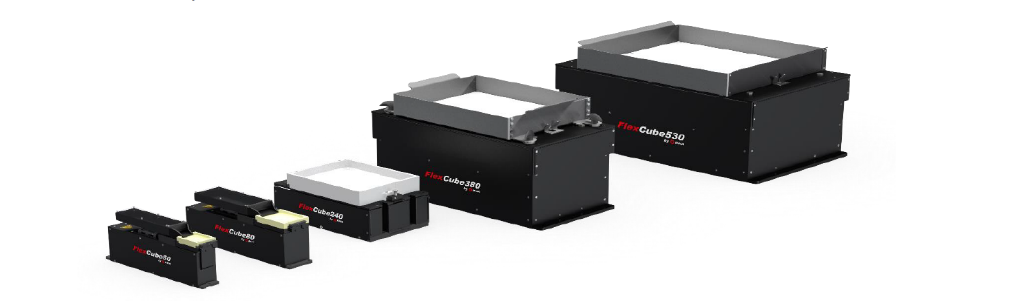

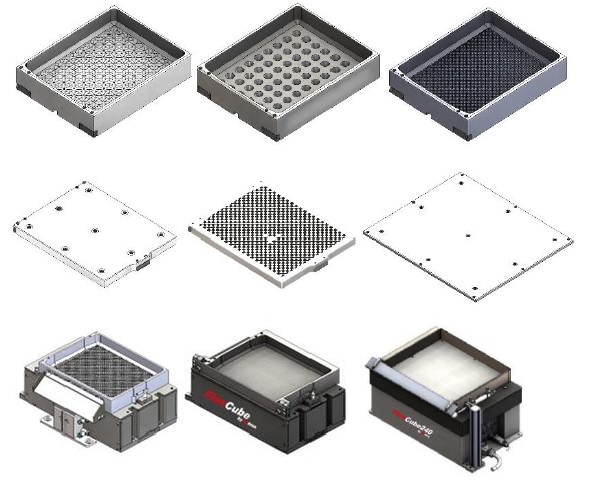

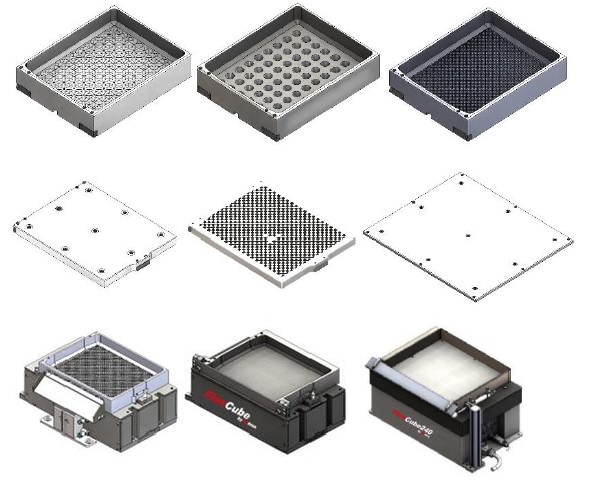

FLEXCUBE™ | INTELLIGENT 3-AXIS VIBRATION SYSTEM

RNA FlexCube™ flexible vibration feeders offer high performance part feeding, pre-orientation and optimal surface distribution of bulk parts and components.

RNA’s FlexCube™ 3-axis vibration technology allows moving parts freely on a platform in different directions. Systematic part orientation can be achieved with intelligently structured platforms. Using RNA’s intuitive HMI interface, the platform vibration parameters can be tuned specifically for an optimal part distribution and fastest resulting cycle time. A functioning part feeding recipe is typically created in less than 5 minutes.

FlexCube 50 | FlexCube 80 | FlexCube 240 | FlexCube 380 | FlexCube 530 | |

Typical part dimensions | <0.1 - 5 mm | 3 - 15 mm | 5 - 40 mm | 15 - 60 mm | 30 - 150 mm |

A | 14 | 15 | 39 | 252.8 ± 0.5 mm | 369.8 ± 0.5 mm |

B | 60 | 82 | 219.5 | 323.8 ± 0.5 mm | 426.8 ± 0.5 mm |

C | 8 | 9 | 26 | 10 mm | 10 mm |

D | 34 | 52 | 150 | 1.5x45° (4x) | 1.5x45° (4x) |

E | 45 | 65 | 195 | ||

F | 8 | 9 | 14.5 | ||

G | 46 | 65 | 171 | ||

Power supply | 24V / 4A | 24V / 6A | 24V / 8A | 24V / 20A | 24V / 20A |

Platform | precision-manufactured platforms adapted to the parts geometry of parts and the task on hand | |

FlexCube | available with and without backlighting available backlighting: Red / white / green / blue / infrared | |

Communication | Ethernet (TCP/IP), Modbus TCP, EtherNet/IP, EtherCAT, PROFIBUS, SERCOS | |

Software | easy configuration and integration via enclosed operating software | |

Miscellaneous | - input for backlighting for synchronisation with vision system | |

- 2 digital inputs/outputs, e.g. for synchronisation of 2 hoppers | ||

- easy installation on machine table | ||

Options | - Platforms with part-specific surfaces | |

- Calibration plates for robot / vision system | ||

- Quick emptying devices | ||

- Ejection system for quick emptying |

Compatible with all parts geometries: 99% of all parts can be separated by this feeding system, including parts featuring complex outer geometries, and highly fragile parts.

Minimum change-over times: easy exchange of part-specific vibratory plates provides for flexible and future-proof production systems.

Extremely gentle part handling with patented 3-axis vibratory system: Parts can be moved in all directions and flipping parameters can be stored for each specific part.

Free movement of parts in all directions thanks to the use of magnetic coil actuators, for optimal acquisition by camera system with the objective of presenting the parts in the shortest possible time.

No transmission of vibrations to the rest of the line thanks to decoupling of vibratory platform from the casing.

Systematic part orientation using intelligent vibration cycles.

Easy configuration with the feeding software.

HOPPER SYSTEMS

- Compatibility: RNA BVL-P hopper systems have been developed to fit the various platform sizes and feeding tasks.

- Plug and play: our hopper systems come factory-tuned and are easily integrated in the complete concept thanks to the enclosed control system. The discharge height is adapted for part transfer to the downstream FlexCube system.

- Demand-based feeding: BVL-P hopper systems are designed for optimized part transfer rates to the sorting platform, which are key to achieving short sorting cycle times.

- Enhanced autonomy: the filling volume is easily adaptable to your needs through the addition of static or upstream hopper units. And of course, communication between these hopper systems can be handled by RNA controllers.

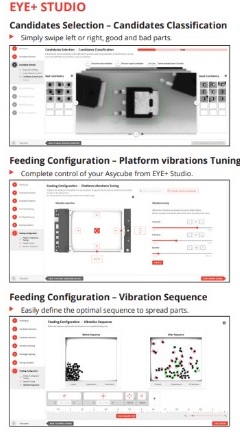

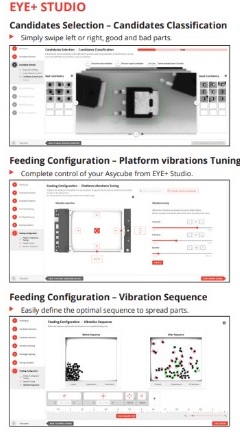

EYE+ | SMART CONTROL SYSTEM

- Easy to use: No previous experience of machine vision required to setup and use EYE+ resulting in faster installation and lower setup costs.

- Intuitive recipe creation and configuration: User friendly interface, with step-by-step instructions and explanations, makes the software easy to follow.

Have a complete new system with calibrated robot and vision setup within minutes. New recipes can be learnt in a fraction of the time compared to conventional models. - Plug and play: Designed to easily integrate with any size of FlexCube and any industrial robot for hassle free set-up. Simple direct connection and pre-defined vision parameters with help tips and graphics mean installation, mounting and setup can be quickly performed without any prior experience.

- All included: Simply accessible via a web browser, no software download or additional licensing required. No 3rd party software or hardware required for a complete system

- Attractive: Highly competitive system costs compared to traditional solutions.

- Compatible with any PLC & industrial robot brand: Command prompts are sent through TCP/IP so EYE+ is compatible with any robot brand giving pick point location for any part.

6-AXIS ROBOT & ASSEMBLY NEST

- Fully integrated: Compatible with customer preferred 6-axis robot, with custom gripper system to suit the application – quick change if required.

- Quick change: Reduce downtime with seamless changeover of both the robot gripper system and assembly fixture nest.

- Customised: Application specific gripper system and assembly fixture nest.

- Double checked: Fixture nest equipped with vision check to confirm efficient assembly, with good parts / bad part unload supplied as standard.

Contact

Send your message to a member of our team

Read our Privacy Policy to learn how we manage and protect your submitted information.